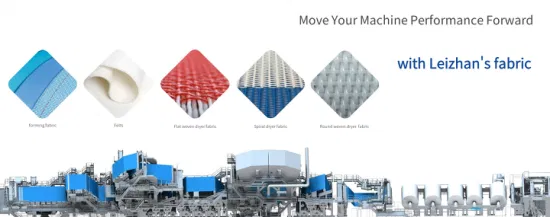

Hard Cotton Polyester Heat Press Felt for Mattress Pad Material

Overview Product Description Paper making felt can be divided into three types: wet press felt, pick up felt and dryer f

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | LZPF-101 |

| Application | All Kinds of Paper |

| Advantage | Long Service Time |

| Delivery Time | Around 20 Days |

| Felt Type | Press Felt, Dryer Fet, Pickup Felt, Mg Felt |

| Felt Layer | 1 Layer, 1+1 Double Layer, 1+1+1triple Layer |

| Transport Package | Export Standard Packing |

| Specification | According to customized |

| Trademark | Lei Zhan |

| Origin | China |

| HS Code | 59113200 |

| Production Capacity | 5000 Ton/Year |

Product Description

Product Description

Paper making felt can be divided into three types: wet press felt, pick up felt and dryer felt according to the uses.Paper making felt possess good air permeability, mark-less, heat resistance, wet resistance, anti-aging, structure stability, anti-worn out, dimensional stability, excellent tensile strength, high linear pressure, easy to operate, long life performance.The main function of the press section of the paper machine is to remove water as much as possible before the paper enters the dryer section to increase the dryness of the paper. Every increase of 1% of the dryness of the output press paper can reduce the drying load of the dryer by 4%. Therefore, it can save energy and increase production; in addition, the press section has the function of appropriately increasing the tightness of the paper, increasing the fiber binding force and paper strength, and improving the smoothness.Key Feature:1. High anti-compaction capacity.2. Extremely high elasticity and recoverability.3. Strong drainability abd larger void volumn.4. Long holding time of wear resistance and plastic strength of felt.5. Smooth felt surface and even pressure distribution.Customizable:According to paper machine and paper, we can change the structure of base mesh. It has the characters of anti-high pressure, good elasticity and filterability, stable size, small elongation, great strength, affective to eliminate grooving, vacuum mark, blind-hole mark and other marks. Suitable to vacuum press, kinds of complex press and other press for producing high grad offset paper, and kinds of high grade paper and paper board etc.

Product Parameters

Our products come from the unique equipment and production workshop, mainly including 1. The carding and pre needling workshop has a closed temperature and humidity control system;2. The internationally advanced 3D multi axis mesh production line for the fourth generation papermaking felts;3. Independent singeing machine (for special paper and tissue paper felts), professional cutting edge and sealing edge machine, etc.

Single layer | Single layer forming BOM felt | Working speed | ≤800m/min |

| Single layer press BOM felt | Paper kind | all kind | |

| Single layer top BOM felt | Line pressure | ≤80KN/m | |

| Double layer | Double layer forming BOM felt | Working speed | ≤1000m/min |

| Double layer press BOM felt | Paper kind | all kind | |

| Double layer top BOM felt | Line pressure | ≤60-200KN/m | |

Triple layer | Triple layer BOM for large roll press | Working speed | ≤1000m/min |

| Triple layer BOM for shoe press | Paper kind | Newsprint, culture paper, high - grade board card paper | |

| Triple layer BOM for hot press | Line pressure | ≥ 200KN/m |

Detailed Photos

Using tips and cautions

Application Before Installation:Inspect the package integrity.Verify the Model No, specification, GSM on the package in consistency with order.Unpack and inspect the appearance and dimension.Installation:Clean paper machine.Verify front and back side and the run direction.Avoid grease staining and damage.Do not draw strongly.Running Without Stock:Align the felt.Wet the felt with clean water.Put proper tension on the felt.Inspect all rolls, press entrance and felt condation.Increase nip pressure.Paper machine creep speed.Further increase tension.Set at normal pressure.Add clean water, detergent or 5% hot caustic to soften the felt.Inject lower pressure steam and vacuum system.Adjust the felt surface.Sufficient run time on the bare machine will improve the stability and durability of felt.Related products

Company Profile

We are a China industrial felt and fabric manufacturer located at Jiangsu province,Xuzhou city. With advantage technology and excellent produce equipment,we provide one-stop service from consultation,process design and optimization , manufacture ,installation , commissioning and personnel training and so on.At the meantime,we can custom design according to customers' requirements. Now, in addition to providing high-quality products and basic services, we pay more attention to providing customers with technical support and a complete set of solutions. Through our professional analysis, we can reduce customers' costs, enhance their competitiveness, and provide customers with one-stop industrial fabric solutions.

Leizhan corporate spirit : "Unity, innovation, pragmatism, and truth-seeking".

Since the establishment of Leizhan, we have insisted on taking customer needs as our core, thinking about what customers think, worrying about what customers need, and striving to achieve customer satisfaction. We insist on growing and succeeding together with customers, and have established long-term stable and successful cooperative relations with customers in 35 countries.

We are united. In today's globalization, we unite with our customers, develop together, and make customers more successful.