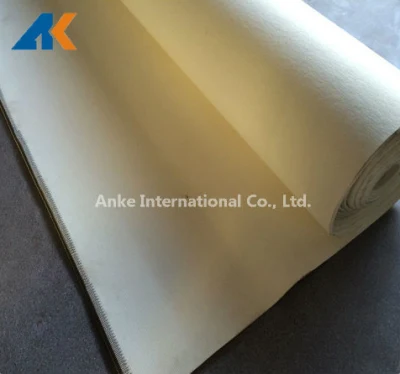

Industrial Filter Cloth Needle Felt Nomex / Fiberglass / PPS / P84 for Bag Filter

ECOGRACE Dust Filter bags widely applied in different industrial dust filtration system or air pollution control system

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | PPS 554 |

| Transport Package | in Roll |

| Specification | 215cm |

| Trademark | ECOGRACE |

| Origin | China |

| HS Code | 56021000 |

| Production Capacity | 5, 000, 000PCS/Month |

Product Description

ECOGRACE Dust Filter bags widely applied in different industrial dust filtration system or air pollution control system dust collector filter elements.Three production lines keeps our delivery time always in time for every order .Filter Felt Nomex , PPS , PTFE , fiberglass , etc.Types of ECOGRACE Filter bags :The type of dust filter bags :Pulse jet filter bagReverse pulse filter bagEnvelope type filter bag

The application / Industry :Baghouse Filtration / Air pollution control systemFoundry / Metal Smelting Asphalt Mixing Power Generation ,Waste treatment power generation plant ,Cement , Gypsum / Lime ProcessingMining.Carbon Black ,ECOGRACE is very speciallized in High temperature filter bags:Nomex filter bag:1. Temperature (°C): Continue: 204, Instant: 2402. Application : pitch mix gas,blast furnace gas in steel factory, gas, tail gas of white char,kiln applications,electric cooker high temperature gas,etc.PPS Ryton filter bag:1. Temperature (°C): Continue: 190, Instant: 2102. Application:waste incinerator,electric station boiler,industry boiler and so on.P84 / PI filter bag ( Polyimide ),1. Temperature (°C): Continue: 260, Instant: 3004. Application:cement kiln,waste incinerator,etcFiberglass filter bag:1.Temperature (°C): Continue: 240, Instant: 2602.Features:low price compared with other high temperature fibers,and stable size,lowshrinkage rate,high intensity3.Application:chemistry,steel factory,metallurgy,cement,etc.Fiberglass combined Felt filter bag:1.Temperature (°C): Continue: 260, Instant: 2802.Features:heavy loads,long life time, reasonable price, strong function etc.3.Application:polluted air and dust in Iron & Steel factory, Melting factory, Cement factory,Petrol chemistry ,etc.PTFE 100% filter bag ,PTFE Fabrics :1. Temperature (°C): Continue: 250, Instant: 3002. Features: strong stability, wear resistance, chemical stability, temperature resistance is particularly prominent3. Application:used in steel, power, waste incineration flue gas filtration and other harsh environments.Application and Size of filter bag :

| Filter Media | Working Temperature | Application | Regular Size (mm ) |

| Nomex Filter Felt | 180-10 degree C. | Asphalt mixing , metal smelting , Gypsum , Cement plant ,etc . | D130 x 2450, D 150 x 3050 , D 160 x 3600 , D150 x 4500 |

| PPS Filter Felt | 160-190 Degree C | Coal boiler power plant , waste treatment power plant ,etc. | D 160x 6000, D127 x 8065 |

| PTFE 100% Filter Felt | 240-260 degree C . | Waste treatment power plant , | D 127 x 3500 , D 130 x 3000 |

| Fiberglass Filter Felt | 260-280 Degree C | Cement Kiln , Steel plant furnace | D 160 x 6000 , 152 x 5000 |

| PTFE memrbane Fiberglass Cloth | 260-280 Degree C , | Cement kiln , steel plant furnace , carbon black plant | D 127 x 36000 , D 130 x 4500 |

We selected INSPEC FIBERS polyamide fibers from Austria LENZING COMPANY, guided by the foreign professional company and then we produced the P84 high temperature resistant needle punched filter felt-one new type of high temperature resistance.

It has three remarkable features:1. Remarkable high temperature resistanceWorking temperature 260ºC. It has enough safe space to deal with the machine stop and accident etc.2. Favorable chemical resistanceIt has been proved that P84 filter bag has the excellent filter value for the acid waste gas, alkali powder and dust in the past waste incineration more than 10 years.3. The efficiency of low back wash pressure and high elasticity mud cake release

| Compositions | P84/P84 scrim | P84 / glass scrim | |||||

| Weight (g/m2) | 450 | 500 | 550 | 800 | 850 | 900 | |

| Thickness (mm) | 2.1 | 2.3 | 2.5 | 2.5 | 2.8 | 3.0 | |

| Air permeability (m2m2/min) | 19 | 15 | 12 | 16 | 13 | 10 | |

| Tensile strength (N/5× 20cm) | Warp | 650 | 700 | 800 | 1800 | 1800 | 1800 |

| Weft | 1150 | 1200 | 1300 | 1800 | 1800 | 1800 | |

| Tensile Elongation (%) | Warp | < 35 | < 35 | < 35 | < 10 | < 10 | < 10 |

| Weft | < 55 | < 55 | < 55 | < 10 | < 10 | < 10 | |

| Broken strength | 2.55 | 2.50 | 2.40 | 3.20 | 3.10 | 2.95 | |

| Working Temperature(C) | ≤ 260 | ≤ 260 | |||||

| Short time Working temperature(C) | 280 | 280 | |||||

| Anti-acid | Excellent | Excellent | |||||

| Anti-alkali | Medial | Medial | |||||

| Anti-abrasion | Excellent | Excellent | |||||

| The stability of water solution | Medial | Medial | |||||

| Finishing treatment | High temperature hot pressing, Singeing | High temperature hot pressing, Singeing | |||||